General principle

Many finishing processes can be applied to ceramics. We can class them into two categories: those applied for aesthetic reasons (polishing, decorations, etc.) and those applied to obtain a specific property (metallisation, surface finish, traceability, etc.)

Detailed description

The main finishing processes are:

- Polishing, which provides a very smooth and shiny appearance or very thin surface finishes.

- The principle is to remove small bits of material, by mechanical abrasion using very fine millstones or liquids with fine abrasives.

- In contrast, micro beading gives a "rougher" appearance.

- Very hard, small beads (sand or glass) are projected at high speed to modify the treated surface.

- Tribofinishing is a form of polishing which gives a very thin surface gloss finish and also rounds off any sharp edges.

- Reproduction, in a workshop, of a well-known natural process which is the abrasion of workpieces in a liquid and abrasive mixture which is stirred over many hours.

- Engraving, which is used for decoration, identification or traceability.

- Engraving is generally performed with a laser and can be superficial or very deep.

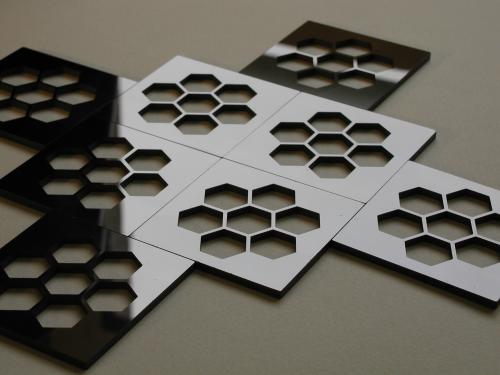

- Deposits of various forms such as paints or lacquers, PVDs, etc. They are used for decoration but also to provide specific properties, such as making a ceramic conductive in certain places, for example.

For more information

Raw material

Finished product