General principle

This process creates a strong bond between the metallised ceramic and a metal using a metal filler (brazing alloy) brought to its melting temperature which wets the metallic part and the metallised layer of the ceramic.

Detailed description

Brazing involves three stages:

- A metal layer is first applied to the ceramic (Metallisation of ceramics).

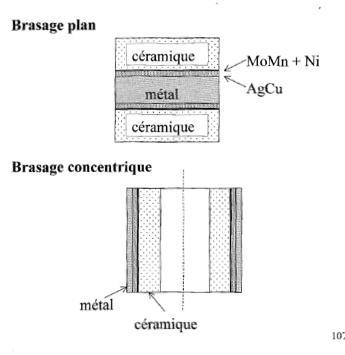

- Jointing of ceramic and metallic components in a support tool (graphite or alumina) with the brazing joint between the surfaces to bond.

- Transfer to the kiln to bring the filler metal to its melting point in order to wet the metallic surfaces, then cooling to solidify the whole part.

Examples of moly-manganese + metal metallised alumina brazing:

Materials involved

For ceramics, the main materials used are very high purity alumina, alumina/zirconia composites, zirconia, ruby, sapphire and aluminium nitride.

The metal components to be brazed are created from metals and alloys such as titanium, OFHC copper, molybdenum, tungsten, platinum, nickel, iron-nickel alloys, and stainless steel.

To bond the metallised ceramic to the metal component, filler metals are used (e.g. Ag-Cu, Cu, Au, Ni-Au).

Advantages and disadvantages of this process

Avantages

- Hermeticity

- Reliable jointing technique

- Resistance to high temperatures (brazing on moly-manganese metallisation)

- Biocompatible (brazing on thin layer metallisation)

Inconvénients

- Costly technique compared to bonding or mechanical jointing.

For more information

Raw material

Finished product