General principle

The first stage of the Ceramic Injection Moulding (CIM) involves combining a ceramic powder with a polymer-based binder to make the mixture injectable. The binder is then eliminated during the debinding and sintering cycles.

Detailed description

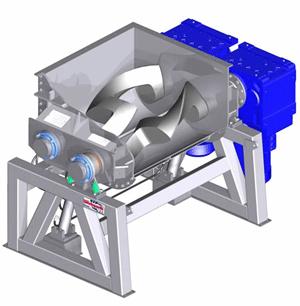

Ceramic powder is generally added gradually to the molten polymer (binder) mixture using agitators or extruders which ensure high shear rates and thereby the homogeneity of the system. Once the mixture is homogeneous, it is then cooled and formed into granules (feedstock) to be injected.

The volume proportion of powder in the mixture or filler rate is in the region of 50% in order to ensure both a good injection capacity and good cohesion during debinding, as well as a high and homogeneous final density. The binders are mixtures of thermoplastics (polyethylene, polypropylene, polystyrene), waxes which lower the viscosity of the binder and create open porosity facilitating its elimination, and surfactant agents to improve the miscibility of the compounds.

The mixture is made by adding the powder to the molten polymer at the melted stage using agitators or extruders to ensure high shear rates. Once homogeneous, it is chilled then formed into granules to be injected.

Materials involved

For CIM, the powders used are alumino-silicates, alumina, zirconia, silicon nitride and silicon carbide.